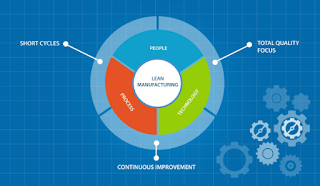

Starting in 2019, we at Ohio Galvanized Tube began to

eliminate waste and focus on becoming a lean company. This has allowed us to

have short lead times in both our fabrication and distribution side of our

business. Not only have we incorporated these principles in our shop, but also

have we switched to a computer software that makes our quoting and management

processes quicker than ever. While we strive to be a more environmentally

friendly company, we want you to know that our fast service will not be

compromised.

|

| Starting in 2019, we began to eliminate waste and focus on becoming a lean company. |

According to TechTarget, “lean manufacturing is a

methodology that focuses on minimizing waste within manufacturing systems while

simultaneously maximizing productivity. Waste is seen as anything that

customers do not believe adds value and are not willing to pay for. Some of the

benefits of lean manufacturing can include reduced lead times, reduced

operating costs and improved product quality.”

We firmly believe that implanting a lean manufacturing strategy

is best for our company, the environment, and our customers. Surely, you’ve

heard this before, but we only have one planet. We don’t get a second chance,

so we are passionate about finding new, creative methods for protecting the

Earth while catering to the needs of the steel tubing industry.

Ohio Galvanized Tube is always looking for new ways to

improve. While we are pleased to have taken these first steps, we recognize

that being a lean company is a marathon, not a sprint. We will continue making

changes to move toward a more comprehensive lean manufacturing strategy. Again,

our focus has always been and will remain our customers. We want to provide each

of you with the best quality products while eliminating waste and being as

efficient as possible.

Curious about other ways Ohio Galvanized Tube is improving? We encourage you to follow us on LinkedIn and to like our Facebook page. Stay up-to-date on everything new that’s happening at Ohio Galvanized Tube and in the steel tubing industry. You can also visit our website at https://www.ohgalvanizedtube.com/ or give us a call at (419) 289-3183.

Comments

Post a Comment